Redacción Alabrent

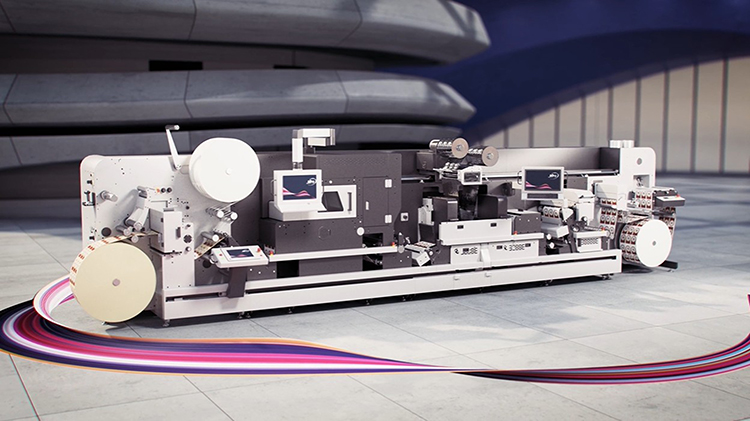

The addition of individual piece options will be of interest to web-to-print businesses looking to provide their customers with enhanced marketing capabilities. The laser will cut the shape of each sticker, providing a cut from the face stock, through the substrate, to the liner. When the web is pulled away from the laser area, the stickers are drawn onto the conveyor system, and the waste is rewound. The stickers then go into a collating conveyor where they can be boxed in batches of the desired pre-set quantity.With the new software designed by the ABG Digilase team allowing increased speed from its single laser head, the upgraded DigiLase 4.0 reduces lead times even further. Combining the latest workflow technology with barcode scanning, which enables the automatic changeover of the jobs, the DigiLase 4.0 can now offer complete flexibility across a range of print-apply applications, including roll to roll, sheet and, most recently, individual piece options. The machine's modular design is fully compatible with ABG's DigiJet module for digital embellishment, meaning that it is possible to print and ship the same day alongside the DigiLase laser technology. This speed and flexibility guarantee a distinct competitive advantage. As an additional benefit, all software code and servicing are provided by ABG, with no third-party involved, making the manufacturer the direct source of contact for all queries.

The launch of the new features for the DigiLase 4.0 represents a step-change in direct from web sticker and label production," said Floriana Montella, DigiLase product manager at ABG. "The inclusion of individual piece options and increased speed will provide web-to-print businesses with increased capabilities at a time when most are looking to upscale their output."

Given the current circumstances, if customers would prefer not to visit trade shows or showrooms to see ABG's DigiLase 4.0 in action, the company can arrange customised remote demos using the customer's files and printed materials.