Redacción Alabrent

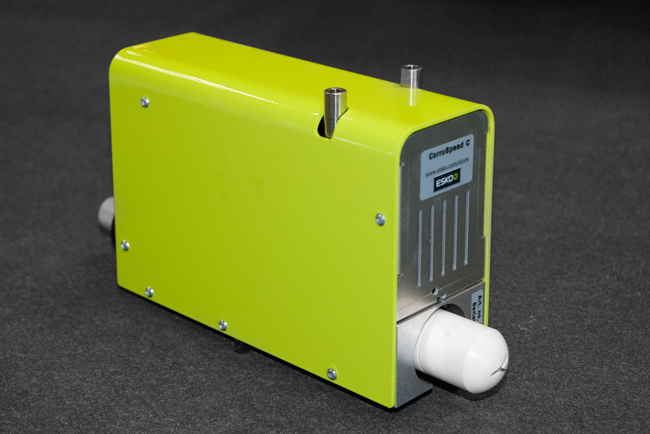

“We saw very high enthusiasm for these new tools at drupa,” says Knut Johansen, Product Manager of Esko, “and have seen fast adoption both as add-on tools for existing Kongsberg tables as well as inclusion in the sale of new tables. Digital cutting of corrugated board has been problematic in both the packaging and signage markets due to the tendency for digital cuts to leave burrs or tags on corrugated board that detract from the quality of the final product. With these new tools, that barrier is eliminated. It is silent and results in a smooth cut similar to conventional die cutting by enabling more aggressive pre-crushed lines that prevent the liner from cracking. It has set a new benchmark in digital finishing.”The new CorruSpeed cutting tools include an innovative floating foot with spring-loaded adjustable pressure that enables cutting of a wide variety of corrugated board types up to 7mm double wall BC flutes. This allows it to crush down on the liner, preventing it from cracking and creating a cleaner cut. It also means that cuts can be accomplished at high speed, improving productivity and throughput. A side or top gauge clearly indicates the level of crushing pressure being applied.

“Real-world experience with these new cutting tools demonstrates both an improvement in cutting quality and a significant time savings, even with corrugated board that has a high level of recycled content,” adds Johansen. “This is a breakthrough product that is unmatched in the marketplace and is another example of Esko’s dedication to playing a leading role in the world of digital finishing for packaging, signs and display graphics.”

www.esko.com/lp/corruspeed