Redacción Alabrent

The C550 press will allow SAICA to expand its wide customer offering with digital solutions. The new digital press works alongside its HQPP Flexo presses and will enable SAICA to continue spearheading the field of corrugated print. Back in 1997, as an innovator, SAICA PACK Viana introduced the first High-Quality Post-Print presses in Iberia. And now it adds a high-volume digital press to its comprehensive product portfolio.With the new addition, SAICA will also be able to offer its customers faster time-to-market, short lead times, and sustainable digitally printed packaging, based on HP’s printing technology and true water-based inks. This single-pass, post-print press will also open for SAICA new opportunities with quality packaging on coated and uncoated liners, to give its clients better flexibility and a wider range of applications for their campaigns, including food-compliance packaging.

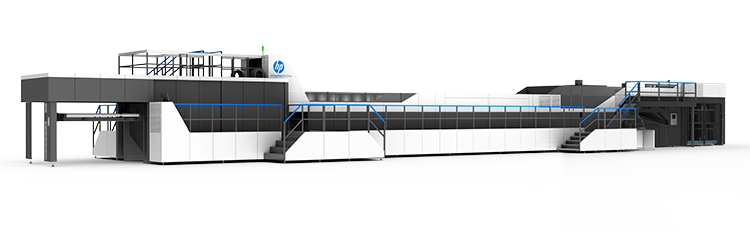

The robust HP PageWide C550, using HP Thermal inkjet technology, supports migration of low to high volume of litho and flexo jobs and optimizes plant production through digital efficiencies that streamline operations. SAICA growth plans include migration of current flexo jobs as well as loading the press with previously outsourced litho work, enabled by the high-quality of print generated by the C550 press.

“We are committed to using the best technologies to drive our group box strategy. We see a definite fit for the HP C550 in our Viana plant handling the volumes that need to be produced to the highest quality. The C550 water-based inks and print quality are a key component for our customers and in driving SAICA’s commitment to key environmental vectors such as sustainability and reduction in water consumption. We are committed to offering the market solutions that seek maximum customization and flexibility in packaging” Said, Félix San Miguel, General Manager at SAICA PACK Viana.

HP’s digitally printed packaging technology helps SAICA meet its sustainability goals

SAICA Group is committed to innovation and sustainability, focusing heavily on implementing sustainable practices to help achieve the company’s sustainability goals by 2025. The new HP’s digital technology allows print-on-demand in short to long runs, reduces obsolescence, waste and warehousing, and contributes to circular economy. Apart from those savings, the C550 printing technology uses an automatic clean-up procedure for the printheads, reducing the water used in press clean-up. It also eliminates the need for harsh chemicals for plate creation – another way to help the environment.

HP’s true water-based inks are odorless and free of UV-reactive chemistries, enabling a wide range of packaging applications, including primary and secondary packaging for sensitive uses such as food and personal care while requiring no additional barriers. The inks can comply with even the most stringent global food safety regulations, including Nestlé guidance and Swiss Ordinance and EuPIA, and support the boxes recyclability and compostabilty.