Redacción Alabrent

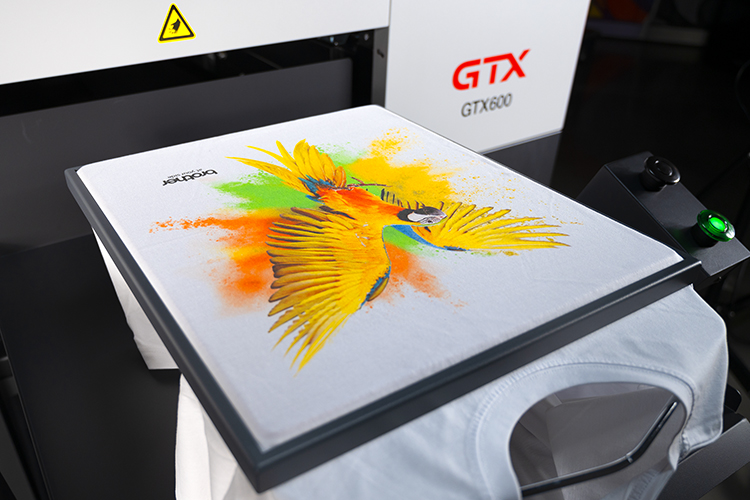

With the Brother developed extra colors, even more vibrant print results can be achieved. Two extra tanks and two extra print heads come with the extension of orange and green ink. Because of the additional inks, the color gamut that can be realized with the printer is increased. More detailed results are achieved as more depth and a wider color spectrum can be visualized. Due to the expansion, the best possible color dynamics can be reached.The many advantages of the GTX600 have been proven in the market and by our customers, such as the fact that the printer is built for mass production at an industrial level, with features you can rely on 100%.

That is the reason why the GTX600 Extra Colors has been further developed on this wellfunctioning basis.

To meet the different needs of our customers, the printer has plates in different sizes to handle a wide range of textiles and creative possibilities. Our up to 24-inch printing plates are easy and quick to change. The printer can automatically adjust the plate height to create an optimum distance between print heads and textile.

Our Brother-made six staggered industrial print heads with internal cooling fans ensure continuous printing operation. Due to the staggered arrangement of the print heads, white ink is printed first, followed by orange and green, with CMYK as the top layer. The inks are filtered and degassed to guarantee optimum print quality up to 1200 dpi. In addition, the builtin air filter always ensures perfect working conditions – even in difficult environments and large production halls.

Sustainability is an important issue and at Brother we want to do our part by offering solutions that have less impact on the environment. Our water-based innobella inks are Oeko- Tex Pass and GOTS certified and come in 9l tanks with less packaging material. The builtin ink mist filter ensures a safe working environment for the operator.

Thanks to our 15 years of experience in direct-to-garment printing, we are able to cons- tantly develop our machines and create the most optimal solution for our customers, with a focus on environment-friendly printing.