Redacción Alabrent

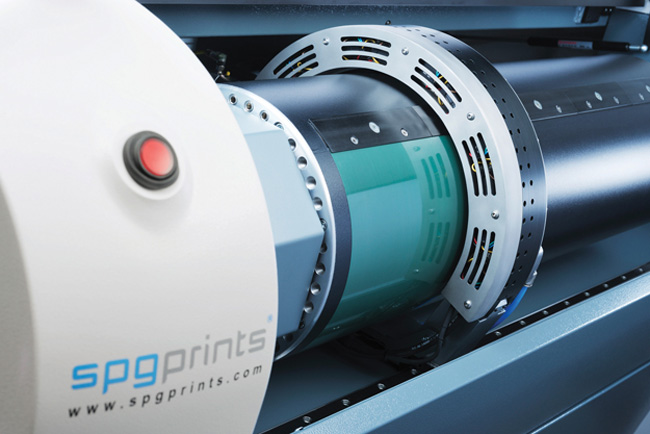

variLEX can be equipped with a multi-beam diode laser system for ablating the black mask and/or a multi-beam diode laser system to directly expose UV-sensitive materials such as screens. Its integrated inline UV-LED exposure system facilitates ablation and exposure in one step. This eliminates the need for offline exposure and ensures sharp printing results.The machine accommodates different mounting cylinders to handle all common plate and screen material available on the market. These include a black anodized vacuum cylinder for flexo plates, a magnetic cylinder for screens and letterpress plates and a hybrid cylinder (vacuum and magnetic) to handle all materials.

variLEX’s diode laser, the inline UV curing and unique software assure repeatable, sharp, and clean printing results. Also, the inline energy-efficient LED UV curing system optimises shoulder steepness and dot-shape consistency.

The imager comes with SPGPrints’ unique software solutions, including the company’s database-driven on-the-fly RIP system, which allows use of all common graphics-industry file systems. The software minimises manual effort by automatically combining the file with the calibrated production settings. Its ‘dot-limit’ software tool offers maximum freedom to shape the image so that the sharpest and smoothest print result is achieved.

Arno Bouwmeester, managing director, SPGPrints Austria, comments: “With its single-step operation, open software platform and world-class quality capability, the variLEX provides a fast, lean and flexible solution for high-end label and flexible packaging pre-press workflows.”