Redacción Alabrent

"The less noticeable a technology, the better!" So says David Clémenceau, Technical Coordinator at the Bourquin Group in Couvet, Switzerland. With the new BOBST peristaltic pump, his wish has been granted: "We installed one eight months ago, and we've never needed to touch it. It runs - it's that simple!" And his satisfaction is no accident: BOBST selected each component for its new peristaltic pump in order to optimise its operation.The Bourquin Group is a national enterprise founded 125 years ago. Specialising in custom packaging for the food industry, it also offers a generalist range. Its original factory is located in Couvet with another, larger, plant at Oensingen in the canton of Soleure.

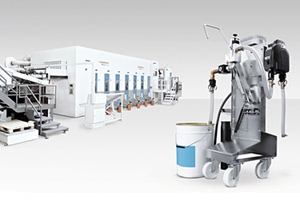

The contrast between the BOBST peristaltic pump and the traditional pumps used on the eight other printing units at the factory quickly became apparent to David Clémenceau, visually at first, since it only measures 20 cm by 20 cm, with a thickness of 5 cm. "You hardly notice it and, unlike traditional pumps, it's extremely quiet and never breaks down!"

The new peristaltic pump is also very easy to use: "Its ink flow can be easily and very precisely adjusted. Our operators didn't need any training. It's also very easy to clean: the water pipe is connected in a single movement."

Traditional pumps are expensive in terms of compressed air consumption, but the BOBST pump doesn't use any. "And it's great at recovering ink, which means substantial savings," David Clémenceau adds.

Savings in ink, water, air and time: the new BOBST peristaltic pump has proven to be an excellent way of reducing printing costs at Bourquin Group with a very quick return on investment.