Redacción Alabrent

Producing at up to 9,000 cycles per hour, the saddle stitcher from Müller Martini is ideal as a high-performance solution for digital saddle stitching, also offering impressive flexibility and reliability for conventional production. The multi-job function, available both for the Prinova and its “big brother” Primera PRO, enables the automatic processing of consecutively different orders. This is a major advantage for printshops working with varying covers but invariable content or frequently producing small runs.Benefits of multi-job production for digital and conventional production:

- Automatic job change: No manual intervention required, saving time and boosting productivity.

- More production freedom: Ideal for hybrid production and custom print products.

- Higher net output: In conventional production, the feeders can continuously receive signature sheets (with the same format) for the new job without the need to stop the machine or clear the feeder manually, significantly increasing the machine’s net output. The machine ensures correct compilation of the products.

Intuitive operation for efficient processes

The operating concept with context-dependent displays makes control extremely user-friendly and speeds up production processes considerably. The Prinova is not only a state-of-the-art machine, but also provides for easy handling and high productivity.

Technical highlights for maximum quality

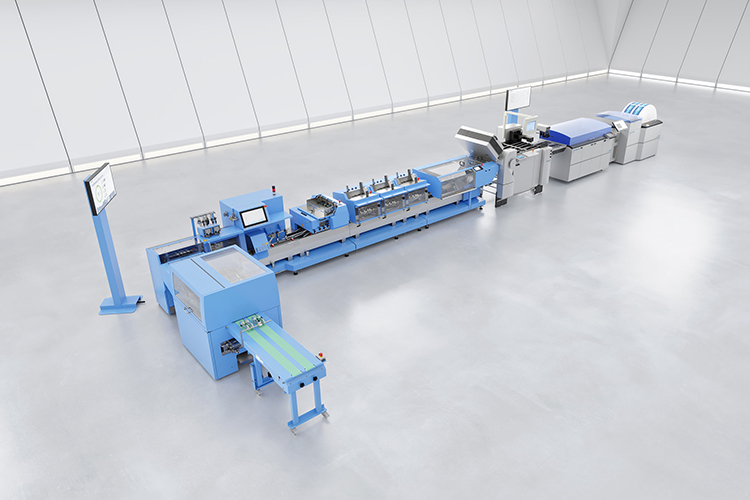

In the digital version, a plow folder connects the digital infeed from the roll or signature with the saddle stitcher. Equipped with the latest control technology, an Asir PRO camera, and a newly developed infeed with optional scoring, it is the technical heart of the Prinova Digital.

The Prinova is available as a completely thickness-variable configuration. Automatically adjusting to the product thickness, the stitching station controls the wire length fully automatically, ensuring perfect stitching. The three-knife trimmer also automatically adjusts to the product thickness. The product is trimmed when still, guaranteeing top trim quality.

End-to-end workflow

For efficient, automated processing of saddle-stitched small runs down to runs of 1, an end-to-end workflow from the print pre-stage to the end product is crucial. In conjunction with the Connex workflow system from Müller Martini, the Prinova Digital covers all process steps, from imposition to the finished product – true to the saying “PDF in – saddle-stitched brochure out.”