Redacción Alabrent

“At drupa, XSYS will demonstrate how to embrace a productive and profitable future with the latest innovations for sustainable printing,” says Thomas Strohe, Director Commercial Excellence. “The world of packaging production is changing rapidly. The pressure on printers and converters is accelerating and XSYS is here to help to alleviate those challenges with innovative products and solutions solving their pain points, most importantly, the demand from brand owners, retailers and end consumers for more sustainable packaging.”Other drupa booth highlights designed by XSYS will include live demos of the award-winning ThermoFlexX Catena+ fully automated plate processing line, the Woodpecker surface patterns for improved quality and reduced ink usage, as well as the expansive portfolio of rotec® precision-engineered sleeves and adapters for process optimization.

Sustainable plate development from XSYS

XSYS proudly unveils the 'nyloflex® eco series', a groundbreaking milestone in flexo plate manufacturing. As the first plate manufacturer to develop this eco-friendly range, XSYS reaffirms its position as an innovator in the field. Visit our booth to explore how 'nyloflex® eco' plates not only deliver unparalleled print quality and consistency but also set a new standard in reducing environmental impact. Experience our commitment to sustainability and innovation by inspecting plate and print samples firsthand.

XSYS will also spotlight the recently launched nyloflex® FTV plate, a significant innovation in the flexo plate market that has already captured the confidence of our customers. This LED-optimized, inherent flat-top dot plate is engineered specifically for the high quality flexible packaging market, setting a new benchmark with its ability to print the finest stable highlights—down to 0.8% at 60 L/cm—and achieve consistent maximum color gamut, ensuring brilliant solids and fine details without the need for additional equipment. Moreover, XSYS continues to lead in sustainable printing solutions with the nyloprint® WS Pro plate, enhancing letterpress printing with its superior printability and extended durability, which contributes to waste reduction in tube and can production. We also showcase the nyloprint® WF Sharp, a water-washable, film-based letterpress plate for the high-end label market, further underlining our commitment to environmental responsibility.

Automated plate processing

The award winning ThermoFlexX Catena+, which has established new levels of efficiency and sustainability in flexo plate processing, will be at show with live demonstrations running several times daily on the booth. Removing human intervention from the process, Catena+ is a breakthrough in fully automated and lean plate processing, enhancing precision, quality, and OEE (Overall Equipment Effectiveness) with reduced waste. This advanced solution has recently been recognized by the FPPA, receiving the 2024 Award for Innovation and Excellence in Prepress.

Further evidence of the company’s investment in highly energy-efficient technologies that help to lower customers’ carbon footprint is provided by the nyloflex® Xpress Thermal System, which offers near elimination of VOCs versus solvent plate processing, low energy usage, and up to 30% less fabric in the developer rolls compared to similar solutions.

Advanced software for high quality, maintenance and control

XSYS is also announcing new software components for its prepress equipment modules, as the company continues to elevate the process towards higher levels of digitalization according to Industry 4.0 principles. Catena ProServX is a cloud-based, real-time equipment monitoring tool for proactive maintenance and superior quality control, helping customers to optimize their OEE, guarantee best quality and minimize waste.

Further software upgrades are due to be launched at the show. These have been developed to support XSYS in driving innovation towards full digitalization and Industry 4.0 operation, combined with its unwavering commitment to sustainability in the packaging printing industry.

Visitors will also be able to experience the impact of Catena Woodpecker surface screening technology through print samples that have been developed in collaboration with leading industry partners. The Woodpecker suite consists of various surface patterns for different printing applications. Woodpecker Nevis specifically optimizes white printing leading to a boost in opacity, whilst reducing ink consumption.

rotec® Sleeves & Adapters

XSYS technology further reaches into the pressroom with its precision-engineered rotec® sleeves and adapters for brilliant printing. The rotec name is synonymous with quality, long-lasting sleeves and adapters, and focused on cooperative partnerships to innovate in line with the printer’s requirements.

Visitors to the XSYS booth can meet the experts to discuss the many sustainable solutions that will help protect their investment and extend product lifetime, as well as reduce the resources required for mounting and handling. The rotec® team will also be introducing new sleeves, stepping into the realm of next-generation sustainability to provide unique solutions for optimizing print performance and operational efficiency with less environmental impact.

Creating a brilliant future for flexo

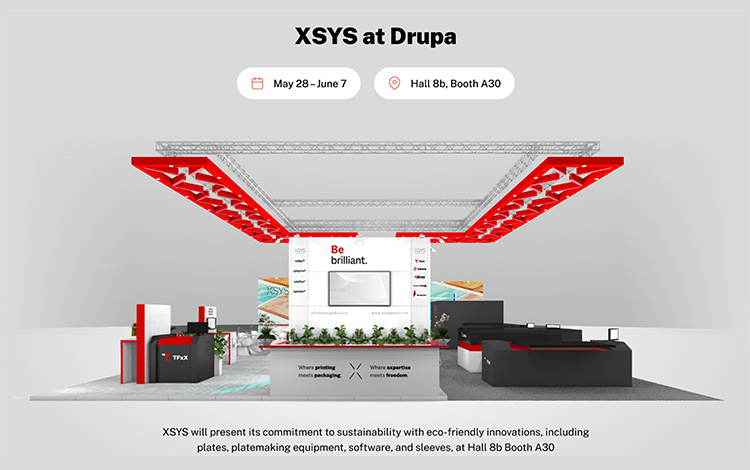

“We Create The Future – the tagline of drupa 2024 – resonates deeply with the mission of XSYS, which is to introduce products and services that enable our customers to ‘Print Solid and Stay Flexible’. The only way to achieve this goal is through continued, sustainable development, bringing to market innovative solutions that minimize the impact on the environment, while maximizing printing quality and efficiency,” concludes Thomas Strohe. “XSYS is deeply committed to sustainability, and we invite you to our booth [A30 in hall 8b] to explore, experience, and acquire our innovative products. Embracing the concept that the new green is blue, we’re eager to showcase our suite of solutions that are driving a sustainable future, helping our customers to ‘Be Brilliant’.”