Redacción Alabrent

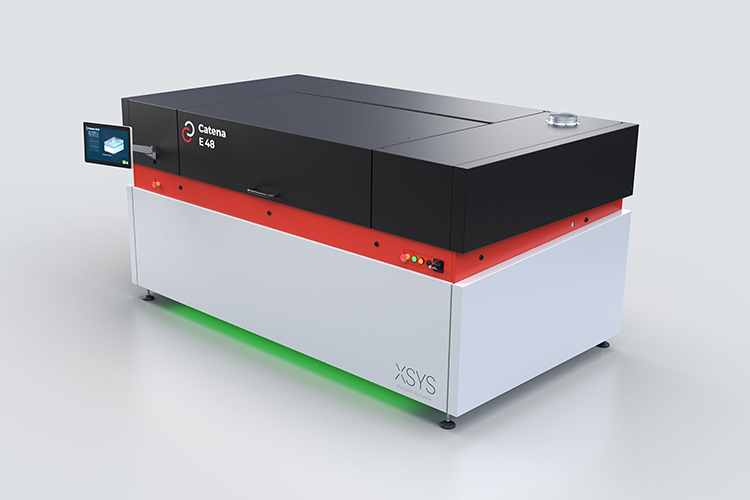

“Catena-E LED exposure technology was first introduced to the market in 2020 and the larger Catena-E 80 model for wide web applications was quickly adopted by platemakers and printing companies serving the global flexible packaging and corrugated board markets,” said Christophe Lievens, Global Sales Director XSYS Prepress. “Now with the Catena-E 48, narrow and medium web printers active in labels, folding cartons, and flexible packaging can enjoy the same excellent plate quality with faster LED exposure and consistent operation which will boost their business.”Exposing plates in a maximum size of 900 x 1200mm (35 x 48”) and up to 6.35mm (0.250”) in thickness, the Catena-E 48 has been built to match the high speed of the TFxX 48-S plate imager from XSYS, which offers an output of 6m2/hr. Exposure takes less than 15 minutes and the unit can be fitted with an automatic plate loading door as an option. Like the Catena-E 80, the new model is also perfect for plates with the finest surface microstructures, such as ThermoFlexX Woodpecker Nano.

Powerful, simultaneous main and back LED exposure ensure excellent plate quality and exceptional productivity, while the enclosed temperature-controlled combined with water-cooled LED modules (fully tested for 20.000+ operating hours) guarantees consistent production of high quality flexo plates. For energy efficiency, the back exposure adapts to the plate loaded, only illuminating LED according to plate size.

To maintain maximum uptime, Catena-E 48 features comprehensive remote support capabilities for calibration, troubleshooting, and preventative maintenance. Replacement of the LED modules, which are reasonably priced, is simple and easy to carry out with basic training or remote guidance from the XSYS engineers.

Excellent feedback is already coming back from early market adopters, such as Tempo Flexible Packaging, which is the first customer in Canada to install the ThermoFlexX Catena-E 48. Bought to replace an older bank exposure unit, the new LED system is allowing the Canadian flexible packaging specialist to improve the quality of its flexo printing and increase its overall productivity.

Craig Labossier, Print Technical Services Manager at Tempo, praised the print quality enabled by the Catena technology, commenting, “With the Catena-E 48, we can hold much smaller minimum dots, and they stay clean throughout the print run, so we can print for longer, which improves productivity and reduces waste. Our customers are also noticing the much cleaner print they’re getting.” He added, “With higher productivity, better quality and increased sustainability, we have truly taken our flexo production to the next level.”

Christophe Lievens concluded, “At XSYS, we continue to expand the offering to the flexo market with solutions that enable printers to be brilliant and serve their customer with best-in-class products. The Catena-E 48 harnesses all the innovative technologies that have placed XSYS at the very forefront of developments in plates and platemaking, and we look forward to witnessing the huge benefits it will bring to the narrow and medium web market.”