Redacción Alabrent

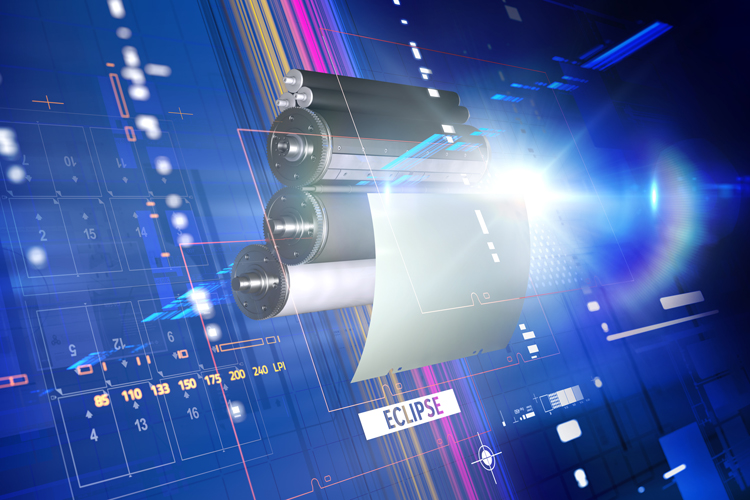

Agfa’s latest innovation, however, distinguishes itself from other process-free plates as this drop-in is just as easy to use as a conventional plate: First of all, the plate keeps the press as clean as can be. Patented process-free technology supports the transfer of the plate coating to the first few printed sheets, instead of to the press as is the case with other process-free plates.In addition, Eclipse is the only process-free plate to provide excellent and stable image contrast, enabling quick visual image inspection as well as recognition by a punch & bending system. That way – even after a week of storage – there will be no mix-ups on press or costly plate remakes. Eclipse keeps its great contrast even after 24 hours in office light, which makes an enormous difference compared to the two hours of other process-free plates. During this period, print quality will be fully preserved in terms of dot gain, toning, start-up time…

Another reason that makes Eclipse an outstanding choice for those desiring to go process-free, is its high scratch resistance. When loading, storing, transporting or mounting this robust plate, printers need not worry about damaging it. The new plate is flexible too, as it can be used with either conventional or H-UV/LED-UV inks.

“You can see the difference with our latest plate innovation,” says Iris Bogunovic, Product Manager Plate & CTP Systems at Agfa. “It eclipses all other process-free plates on the market as it combines superior and stable image contrast with easy handling and clean operations. Several early adopters have already confirmed this.”

A balanced proposition

Eclipse complements Agfa’s offset printing plate portfolio, which meets printers’ needs in different ways. “We are continually looking for ways to stay ahead of the curve and to provide the highest added value to our customers,” said Guy Desmet, Head of Marketing Offset Solutions. “There is no ‘one-size fits all’ when it comes to printing plates. Our portfolio consists of conventional, low-chem, chem-free, and process-free plates. We will always discuss the ideal solution with printing companies, based on their needs and preferences.”

Eclipse is part of Agfa’s ECO³ approach of sustainable innovation, which encompasses hardware, software and consumables that make prepress and printing operations cleaner (ECOlogy), more cost-effective (ECOnomy) and easier to operate and maintain (Extra Convenience). ECO³ extends from the prepress environment into the press room with unparalleled ink saving and press standardization software packages that reduce make-ready time and paper waste.