Redacción Alabrent

Having partnered with HP Indigo for over fifteen years in the development of digital printing solutions for label printing, Esko and HP Indigo are focussed on delivering next level prepress workflow automation across the entire packaging supply chain.Speaking at the event, Adi Levy, CEO of PEERPRINT Ltd., a leading Israeli label and packaging converter utilising HP Indigo digital presses and the recently launched version of Esko Automation Engine for prepress workflow automation, said: “The difference that the combination of these technologies is making to our business is astonishing. We have increased our productivity by up to 50% since implementing Automation Engine in our facility, which took less than one week to install. The speed and accuracy of jobs now reaching the press is outstanding, enabling us to grow and have more flexibility to respond to our customers’ needs.”

Esko President Mattias Byström commented: “Delivering easy to use, turnkey solutions to simplify operations, driving value and efficiency, is core to Esko’s strategy, and our collaboration with HP Indigo ensures we have a comprehensive offering. Our latest Automation Engine offers an ‘out of the box’ style solution for label printers to quickly and easily deploy using pre-loaded industry best practice workflows, and the benefits for companies like PEERPRINT are clear for all to see.”

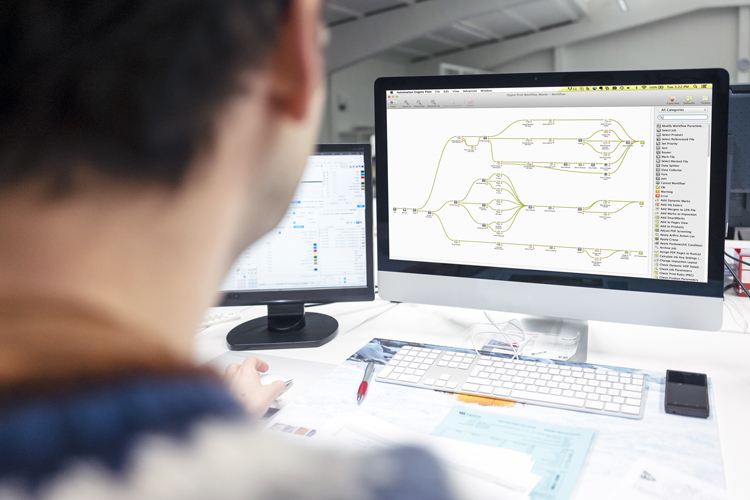

As a web-based workflow solution, Automation Engine automates prepress tasks, speeds up the process, reduces errors and minimises the need for operator intervention. As a result, Automation Engine enables converters to grow production capacity without increasing headcount. Equipment efficiency and productivity is enhanced and the intuitive nature of the technology ensures no prepress expertise is required in house at the label converter.

Esko Automation Engine ensures label converters can address workflow automation quickly and simply. The latest pre-configured Automation Engine can be up and running in under a week or a bespoke solution can be designed to the specific converter environment. Once familiar with the best practice workflows, customers can also further finetune workflows to best match the particular challenges of their production set up.

Alon Bar-Shany, General Manager of HP Indigo, commented: “Converters are experiencing increasing demand for short run work and faster response times. Globally, HP Indigo digital presses are the leading technology designed to respond to this market trend and it’s clear that prepress automation is key to maximizing overall productivity for converters. By automating the prepress, jobs can be delivered faster and more accurately to press to maximise asset utilization. Working with ESKO we are able to provide a market-leading end to end solution to meet the needs of our customers just like PEERPRINT.”