Redacción Alabrent

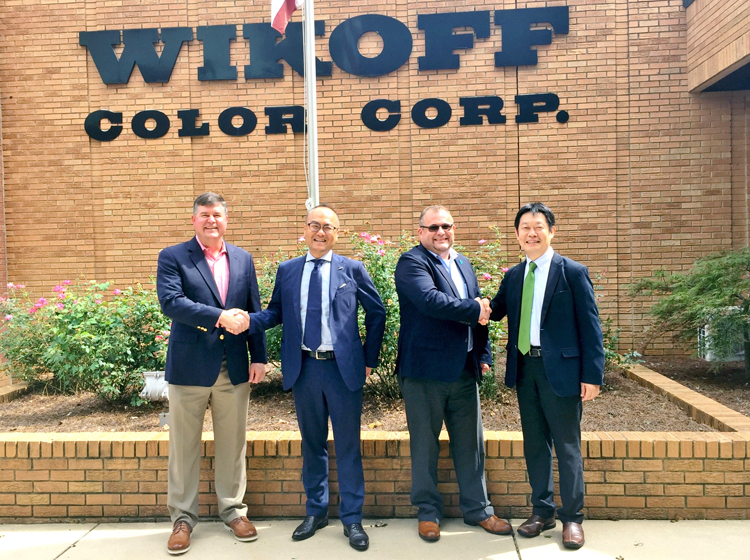

“The U.S. is a large market and very important to Asahi,” states Aki Kato, Managing Director at Asahi Photoproducts. “With platemaking moving closer and closer to the printing press, it is a significant benefit to us and to the end customer to have their trusted ink and coatings supplier also provide their flexo plates.”Wikoff Color will have access to the full range of flexographic plates from Asahi Photoproducts, including to its popular AWP™ water-washable plates with Clean Transfer Technology.

“We are delighted to enter into this important relationship with Asahi Photoproducts,” said Joe Kubasiak, Market Manager for Flexible Packaging at Wikoff Color. “As a company, our focus is on sustained, profitable growth rather than short-term results. In entering into this relationship, we are making the investments necessary for its success by setting up a technical center and hiring the necessary staff in order to train our customers on how to get the best possible quality from Asahi photopolymer plates. We are very excited about the growth this will offer us in the future and our ability to deliver increased value to our customers.”

Clean Transfer Technology: The Details

A feature of many of Asahi’s flexographic printing plates, Clean Transfer Technology enables a clean ink transfer and prevents ink accumulating on the plate surfaces and shoulders in screen areas. This leads to fewer cleaning intervals and reduced press downtime, as well as significant quality improvements. Precise plate register achieved with Asahi plates ensures very high quality process printing with a fixed colour palette, minimizing the need to use and manage spot colour inks.

Clean Transfer Technology allows a kiss-touch printing pressure setting. It makes use of low plate surface tension, made possible by a specially engineered Asahi polymer chemistry, to inhibit liquid flow. The ink forms a globule, with a large contact angle and high pinning point. This results in a cleaner and more homogeneous ink transfer from plate to substrate, helping flexographic printers meet the ever-increasing quality demands of their customers.