Redacción Alabrent

Ricoh ProcessDirector software combines core capabilities with optional add-on features to allow flexible control of critical communications output. It streamlines operations, improves process integrity, enhances operator productivity, reduces errors, and helps to lower costs. It is also the backbone software of Ricoh Automated Document Factory (ADF) solutions.The Pre-printed Forms Replacement feature makes white paper manufacturing a reality. PSPs can now print jobs on plain paper that previously required pre-printed forms. It dynamically redefines AFP and PDF files, allowing content that was printed on the pre-printed form to be added to the data in the print file.

Eef de Ridder, Director, Commercial Printing,of theCommercial and Industrial Printing Group, Ricoh Europe, comments: “PSPs can now modify and eventually replace solutions that depend on inventories of pre-printed forms. For example, sheet fed applications running on pre-printed forms can be migrated easily to white paper on continuous feed, while maintaining production flexibility to produce short runs or reprints on sheet fed devices. Business logic within the workflow can dynamically select the most appropriate output method to help optimise device usage across the production floor. It can also help consolidate jobs into large print runs and reduce or eliminate inventories of pre-printed forms. Operator time and cost savings can be made too.”

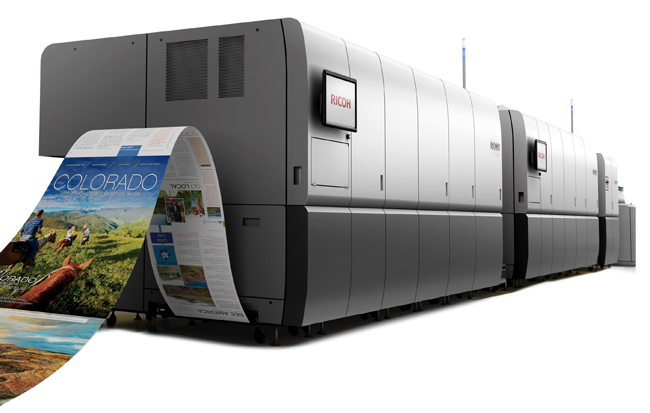

Another feature of ProcessDirector v3.6 is the ability to record the amount and type of ink used by a job printed on Ricoh Pro™ VC60000 and Ricoh Pro™ VC40000 high speed inkjet systems. It reports ink usage for each of the colours for every job. For any reprints, ink usage is added to the original number and stored in cumulative usage counters for each job.

The User Interface has also been refreshed with the most common operator tasks added to the main page. It also includes new portlets that show system health, job status, and device status with easy to understand graphics.

De Ridder adds: “These updates are all about making the lives of PSPs easier. Streamlined production, a closer eye on ink usage and quick to assess figures all combine to make the production environment more efficient and effective.”