Redacción Alabrent

Label converters are increasingly challenged with the growing number of shorter runs, faster cycle times, more SKUs, and stricter regulatory compliance requirements and a mix of conventional and digital printing processes. There is zero margin for error or time loss, and on top of all of this, there continues to be severe margin pressure. In order to address these challenges, label converters must standardize and streamline production flows, taking out as much manual intervention and automating as many repetitive tasks as possible. Implementing standard workflows supported with web-based project management and collaboration tools are essential business improvements as label converters work to stay competitive, and Esko is leading this charge with over 5,000 workflow installations worldwide. Yet many label converters still report that they struggle with the perceived complexity of setting up, implementing and maintaining such workflows and project management tools.“We are committed to Simplify Packaging,” states Udo Panenka, Esko’s President. “In bringing these pre-configured workflows to the label converter community, Esko is responding to a growing industry need for easy-to-use and easy-to-deploy yet robust and proven workflow solutions. These simplified turnkey workflow solutions, based on decades of experience, take complexity out of the supply chain in areas where major bottlenecks and time losses often occur.”

Packaging Simplified: Optimized Workflows up and running in a few days

To help label converters address these challenges, Esko builds further upon its workflow automation software and will be introducing a range of powerful, turnkey packages that are pre-configured to meet the needs of specific applications. They are designed to be easy to implement and deploy, removing complexity and delivering fast results. At Labelexpo Europe, Esko will be demonstrating two such solutions for label converting:

- WebCenter Essentials. A turnkey project management bundle for label production

- Automation Engine Essentials for Labels, a turnkey workflow bundle for label prepress workflow automation

WebCenter Essentials for Labels

In the label production process, customers report that the quality of incoming data and the duplication of assets is an ongoing challenge, and that getting final customer approval is an inconsistent and long process. As more and more short run jobs need to be processed, and many of these process steps are manual touchpoints, this leads to time losses in job preparation. Furthermore, locating existing printed and digital assets can be cumbersome, and there is overall lack of visibility into the process. Because there is no audit trail, customer service staff often spending up to 70% of their day answering customer questions on order status. Automating this process with transparency and a single source of truth saves time and takes the risk of errors out of the process.

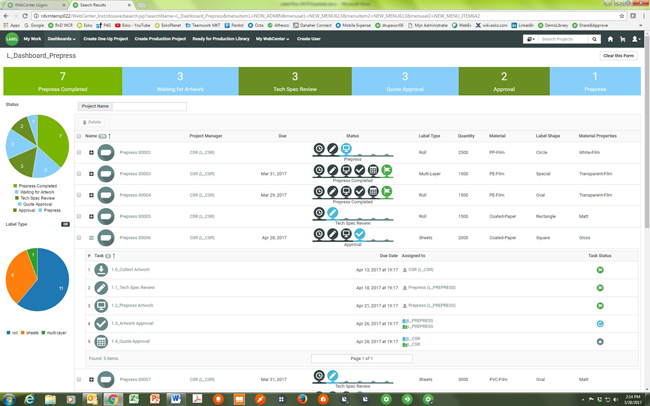

WebCenter Essentials for Labels is a turnkey, out-of-the-box solution with pre-configured process flows. The built-in graphical viewer coupled with approval tools allows for the review and approval of both 2D and 3D assets. The software manages a database of centralized digital assets, allowing easy search for assets and re-ordering of existing labels. It also comes with a dashboard and built-in operational reporting. Once installed, WebCenter Essentials for Labels drives a true paperless process. It makes it easy for both converters and their customers to always know exactly where jobs are and at what stage they are in the process.

WebCenter Essentials for Labels can be integrated with Automation Engine to both smoothly integrate the prepress workflow and standardize the entire process.

WebCenter Essentials for Labels can be a SaaS solution or deployed on premise. Since the solution comes with a pre-configured setup, onsite deployment, including go-live assistance, can be achieved in less than one week.

Automation Engine Essentials for Labels

The prepress workflow for label printing consists of a series of fairly well-known steps, including preflighting, adding and checking barcodes and content, trapping, step and repeat, and adding marks and control strips. Doing this work manually can create capacity and throughput problems, with prepress often being a bottleneck, causing delays that affect the entire plant. Label converters today understand automation is the way forward. The Automation Engine Essentials package is tailored to make it extremely easy to adopt workflow automation and to immediately create additional production capacity to deal with the growing number of jobs smaller without adding extra headcount.

Automation Engine Essentials for Labels offers an out-of-the-box pre-configured workflow that addresses most of the essential prepress tasks for all labels, no matter what printing technology is used (digital, flexo, offset or gravure). The software can be installed and implemented and put to action with full operator training in as little as three days at the customer site.

Automation Engine Essentials for Labels gives label converters a reliable solution that allows them to ramp up their prepress productivity in an easy and cost-effective manner. The Automation Engine Essentials workflow is scalable and can grow with the customer’s business. The software can be upgraded with more functionality, such as automated quality control, color management and output device control, which deliver higher throughput and can be plugged into the customer’s existing business system.

Developments don’t stop here. Esko announces that by Labelexpo Europe it will have transformed the user experience for Automation Engine Essentials for Labels entirely by running the application’s GUI in a browser. The re-engineered user interface will make it even easier and more intuitive for operators to launch jobs in pre-configured workflows.

Also by Labelexpo, Automation Engine will be further enriched with a powerful color preflight function. This automated tool is built on patented Esko color technology. It analyzes the artwork and determines the best color space and ink separations to print the job at the right quality. Automatically this tool determines whether if the job will standard process colors, extended gamut and/or spot colors, and as such drives jobs for the right output device.

“With these turnkey workflows dedicated to label production, we make it really easy for label converters to deploy fully-featured automated workflows that come with unique functionality and connectivity no one else can offer today,” said Bernard Zwaenepoel, SVP Software Business for Esko. “Based on more than 30 years of packaging and labels industry experience, we are once more leading the way with a compelling offering. Our first customer feedback has been overwhelmingly positive and has encouraged us to develop similar turnkey workflow packages for other packaging, sign and display applications.”

Availability

Esko is making the turnkey Automation Engine Essentials for Labels and WebCenter Essentials for Labels commercially available on a worldwide basis in the second quarter of 2017.