Redacción Alabrent

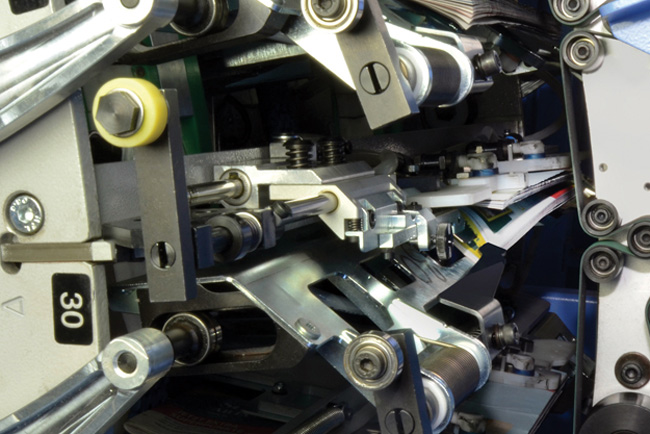

Muller Martini's FlexLiner inserting system is now even more flexible. It can now also open products without a low folio lap or high folio lap. Products trimmed on three sides and products in the tabloid format, such as magazines or municipal gazettes, are gently opened in the center using a blade-like slide and prepared for the inserting process. The inserts are then inserted without any loss in performance. Magazine opening is available as an option and can be easily retrofitted on existing FlexLiners.Flexible Uses

Newspapers have not been the only products to be finished in the mailroom for some time now. Direct-mailing companies also use the FlexLiner inserting system from Muller Martini to put together mail shots. Carrier products, whether they are covers or tabloid products, are opened using a sucker unit or low folio lap unit, and the gathered inserts are reliably inserted.

The FlexLiner is also used with suction opening to place inserts into inserts at high production speeds. This is an additional attractive business model that has proven itself in the market and now accounts for around 5 to 10 percent of insert volume.

New Product Configuration Options

With FlexFeed selective main product feeding, customers have entirely new opportunities to set themselves apart from the competition with the FlexLiner. The main sections can be fed selectively to the inserting machine via up to five feeding stations, which can be loaded manually from the FlexiRoll buffer system or directly from the printing press. Alternatively, up to four inserts can be positioned on the front or back page of a main section as FlexAds (onserting). In addition, an insert can be affixed to the front or back page of a main section as an AddOn. In that prominent position, every FlexAd stands out from the crowd.