Redacción Alabrent

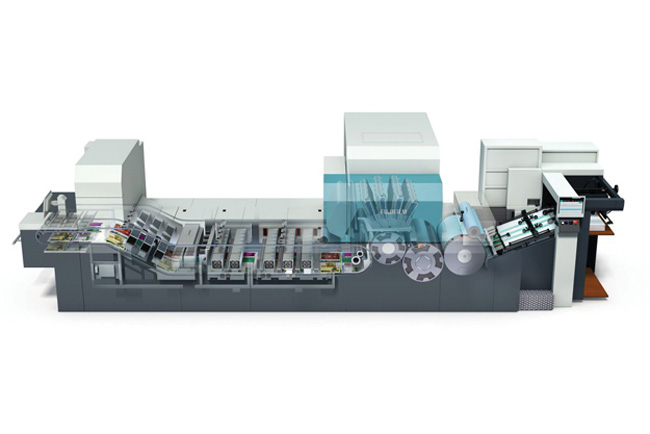

Fujifilm announces the launch of its next generation B2 sheet-fed digital inkjet press, the Jet Press 720S. Featuring a number of key enhancements, the press sets a new standard in digital printing in terms of quality and consistency, production uptime, personalisation and variable data, and application flexibility. And, with an improved business model, the Jet Press 720S is set to transform the world of short run commercial printing.In the rapidly changing print industry, shorter runs, faster turnarounds and print-on-demand are now all standard requirements for print service providers. However, commercial pressures mean that optimising production processes by, for example, minimising downtime due to maintenance, and creating a differentiated service offering are rapidly becoming the difference between success and failure in this market. Fujifilm’s Jet Press 720S B2 digital inkjet press can help printers overcome these challenges and establish a differentiated and compelling service offering in a highly competitive market.

a) A new standard in print quality and consistency

The Jet Press 720 was renowned for its ability to produce the best digital print quality in the industry, and the Jet Press 720S builds on this reputation. The SAMBA™ printheads – the industry’s most advanced single pass printhead technology – can achieve native resolutions of 1,200 x 1,200 dpi. The Jet Press 720S features a new generation of SAMBA™ printhead, with each B2 width print bar built up of 17 individually replaceable modular printheads, each with 2,048 nozzles. The print bar also takes advantage of unique VersaDrop™ technology, allowing the size and shape of each ink drop to be precisely controlled and placed on the paper. This guarantees high print quality and consistency, with no on-press tweaks necessary.

In addition, the Jet Press 720S benefits from a number of adjustments that maximise the consistency and ease with which ultra-high quality print can be achieved, reducing operator time and involvement. Modifications have been made to the ink jetting, print drum surface and paper vacuum control, which enhance all aspects of quality, but in particular reduce paper deformation in highly inked areas.

Print quality is monitored via a CCD sensor, which scans every sheet and makes necessary alterations to the way the ink is discharged from the printheads. In the Jet Press 720S, the proprietary In-Line Sensor (ILS) system is mounted immediately after printing, which means it can detect and correct any nozzle and ink deposition inconsistencies in real time, and make the necessary adjustments sheet by sheet.

Finally, Fujifilm’s high performance water-based VIVIDIA inks, which have been developed to match the SAMBA™ printheads, deliver vibrant colours, extraordinary fine text, excellent skin tones and incredible flat tints on the widest range of standard offset paper. The inks have been further refined for the Jet Press 720S, optimising the combined performance criteria of quality, drying and ink rub-off from sheet to sheet which, when combined with a new drying system, result in sheets that emerge from the press either dry enough to re-work immediately, or soon after printing. The VIVIDIA inks also retain the de-inking and Toy Approval characteristics of those in the Jet Press 720.

b) Enhanced variable data handling capabilities

The Jet Press 720S features a completely new system for handling variable data and personalisation. Although it is a single sided machine, it takes advantage of a system that prints a barcode in the non-image area of every sheet immediately after the paper leaves the input sheet stacker. Once the first side has been printed, the sheets are turned over and loaded into the stacker again. The press reads the barcode on every sheet as it leaves the stacker and downloads the correct page information before it prints the second side, guaranteeing front and back page matching. This can all be achieved at the full press speed of 2,700 B2 sheets per hour.

This feature allows variable data printing and personalisation on a single sided press, but also means versioned applications are much easier to print, or that applications can be printed in page order to simplify print finishing or post print logistics.

c) Maximum press uptime

The Jet Press 720S has been built as a workhorse production press with maximum uptime to produce high quality, short run print all day, every day. The advancements include a modified mechanism to feed paper onto the drum, a sophisticated paper height safety detection system to reduce the risk of paper jams, and a significantly enhanced printhead cleaning regime.

Data handling developments have also been introduced on the Jet Press 720S which speed up job setup and download, thanks to the combination of the power of Fujifilm’s XMF Workflow and the introduction of new high capacity data servers. XMF Workflow provides an intelligent job queue that controls the imposition, workflow automation and all aspects of colour management automatically.

Finally, the introduction of new modular printheads significantly reduces the necessity for system downtime and minimises breaks in production for press maintenance.

d) A new business model

Thanks to a number of technical and manufacturing advancements, Fujifilm has been able to modify the business model and open up the opportunities this press brings to a much wider range of commercial printers. As a result, a wide variety of applications such as coffee table books, photography portfolios, brochures, variable data direct mail, book covers, calendars and art posters can be printed on the Jet Print 720S to generate new revenue streams for forward-thinking print providers.

Takashi Yanagawa, senior vice president, FUJIFILM Europe GmbH comments: “Digital print has come a long way in the last twenty years, with inkjet technologies now coming of age in their ability to transform commercial printing. However, the commercialisation of these technologies is a long road that many companies are on. Within Fujifilm, we have been at the forefront of these technological developments since 2004, and we are delighted to be launching a next generation B2 inkjet press.”

He concludes: “Within the commercial printing market, the ever increasing competitive pressures to improve efficiencies and diversify, combined with a market dynamic where run lengths are decreasing every day, mean there is growing interest in new B2 digital presses. Our next generation Jet Press 720S leads the market in terms of quality, reliability, press uptime and application flexibility, thanks to our industry-leading inkjet technologies, and sets new standards in digital printing. Combined with a new business model, we are excited about the future and look forward to explaining to commercial printers how this press can help transform their businesses.”