Redacción Alabrent

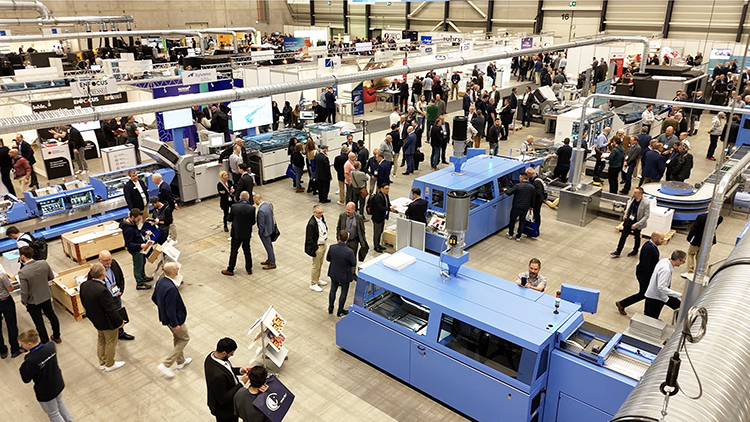

With 6,800 participants and 120 exhibitors presenting 40 live solutions, the event grew slightly once again. "We are proud that, together with our partners, we were able to present pioneering solutions during the four days of the trade fair that will shape the future of the digital printing industry," emphasized Bruno Müller, CEO of Muller Martini.Impressive smart factory solutions

Three of these solutions captivated countless visitors to the Muller Martini booth. All three Smart Factory applications on display impressively demonstrated how Muller Martini can set new standards for end-to-end production processes in collaboration with its partners. Visitors experienced how a finished softcover book was produced inline from both the white roll and the white sheet – from the digital web-fed or sheet-fed printing machine to the cutting robot with subsequent sorting line, fully automated and without manual intervention. The Prinova Digital saddle stitcher on show also produced eight different saddle-stitched products in very short runs from the roll in a continuous process.

End-to-end networking

Muller Martini played all the cards when it came to connectivity at its stand. The Connex workflow system, key technology for the production of individualized print products, controlled all three lines from the digital printing press to the finished sorted product stack. The seamless integration of all production steps, from impositioning the print data to sorting the finished products, fascinated the trade visitors.

Sebastian Birzele, Head of Bindery at the German printing company C.H.Beck, was also particularly impressed: "Muller Martini has networked everything that can be networked on its booth. From the white roll to the finished book – it's fantastic to see how everything works seamlessly." He highlights the Vareo PRO perfect binder and the InfiniTrim cutting robot, which are perfect for digital printing productions, especially due to the elimination of changeover times. "This is going in exactly the right direction." The ability to implement individual customer requirements quickly and efficiently with these networked solutions is a decisive advantage in today's fast-moving printing industry.