Redacción Alabrent

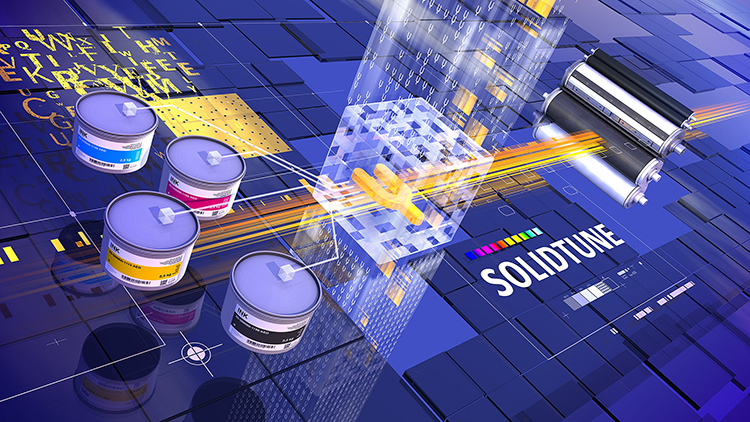

SolidTune has been developed with the specific challenges of packaging production in mind, building on the success of the crucial elements of InkTune and PressTune, which are part of the highly regarded Agfa ECO3 program for sustainable innovation. The new technique applies a unique algorithm to the solids and text, after screening prior plate imaging. This process reduces the amount of ink needed for printing by an average of 3%.SolidTune is available on license in Apogee and Amfortis prepress workflows and can be used with any screening technology, including Agfa SPIR@L.

New technology innovation for packaging

As the last stage of the rendering process, SolidTune applies a unique ink saving algorithm to the solid 1-bit pixels, before final output. Unlike other solutions, the software has been devised with unique edge protection, meaning the algorithm ensures the edges of the solids are preserved to keep the print clean and crisp. This helps to create a better printable 1-bit file for offset packaging printing, where spot colors are often printed as solids.

“The packaging market is growing, and the opportunity is growing for converters, meaning they are constantly searching for new technologies that can help them deliver even better print quality with strong colors, but at cost-efficient levels,” says Andy Grant, Agfa’s Global Head of Software.

“We are now ramping up our unique offering for the demanding packaging market by leveraging our deep expertise in offset printing to introduce innovative solutions, such as SolidTune, that will have a considerable impact on the bottom line for the converter and the long-term sustainability of the process.”

SolidTune: less ink, faster production

Delivering exceptional ink-saving benefits, this new approach naturally shortens the overall production times, as the thinner solid ink film enabled by SolidTune takes less time and energy to dry. And with faster drying, downstream processes such as finishing and die-cutting can take place sooner, allowing converters to respond to demands from brand owners for faster delivery and also to save on warehouse costs.

Furthermore, the implementation of SolidTune into the workflow improves ink distribution and reduces problems with ink offsetting from one impression to the next. There will also be less force on the substrate from the ink system, which prevents plucking (or picking) of fibers from the top paper layer; a problem that is known to cause reduced image quality and potential rejection of jobs.

“This clever tool, which is very user-friendly and simple to impose during the rendering process, provides quite significant improvements in print quality,” states Grant.

SolidTune can be combined with any screening but works optimally in combination with SPIR@L – Agfa’s revolutionary patented screening technology which was extended from commercial into packaging printing in 2021 – to achieve even bigger ink savings.

SolidTune & SPIR@L screening enlargement

Grant concludes, “SolidTune is another innovation that Agfa added to its ECO³ program to maximize ink reduction and value whilst still delivering the highest quality possible and putting converters at the leading edge of innovation.”