Redacción Alabrent

The recently launched XPS Crystal Certification Program recognizes those plate making businesses that consistently produce superior flexo plates which lead to superior flexographic print quality. “The new scheme is a great way for companies to communicate their ‘best in class’ service offering to their supply chain partners and customers,” said Pascal Thomas, Director of Flexo Business at Esko. “It’s a confirmation of flexo platemaking excellence providing reassurance of best practice in production processes and consistent quality of final print.”The certification scheme was developed specifically by Esko to ensure the entire supply chain can meet the exacting needs and requirements of brands and converters in terms of predictable and accurate plate quality and the highest plate making consistency available, for any given photopolymer. Introduced following the popularity of its very successful HD Flexo certification program for flexo platemaking, the new certification is offered as part of the XPS Crystal Hardware Care Plan, ensuring sustained quality improvement as opposed to a one-off effort to secure certification. The process can be started either on installation, during a preventative maintenance visit, or upon request.

“Certification is valid for 24 months,” explained Pascal. “During this period, Esko supports members’ quality control by verifying both imaging quality and the processing quality of equipment in comparison to the Esko’s ‘XPS Certified Plate Reference’.

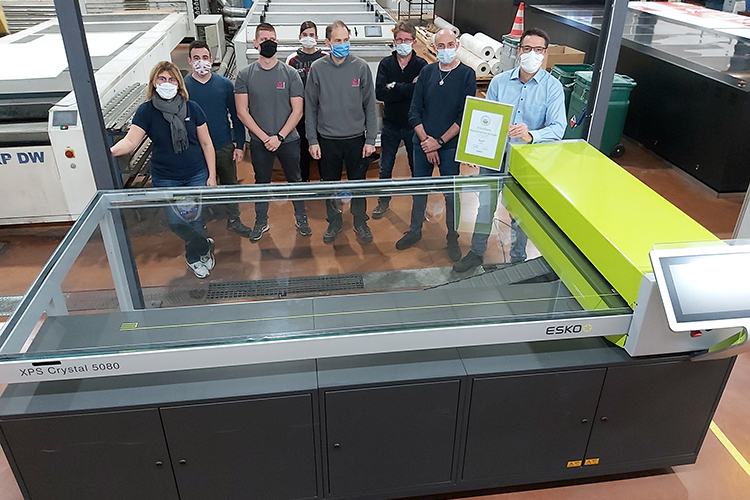

“Achieving certification means that members can assure their customers of optimum quality and performance in their plates and resulting print,” he said. “We’re delighted that Medialliance, a business with a stellar reputation and with whom we have worked closely for many years, has become the first of our global partner businesses to successfully achieve accreditation.”

Olivier Barbier, Project Manager with Medialliance Graphic Bourgoin Jallieu, said that as the business was always keen to be at the forefront of industry advances, the company was thrilled to be the first to successfully complete the certification process.

“Here at Medialliance, we have secured a position as a go-to partner for companies looking for support with packaging and brand identities,” said Olivier. “Honing our expertise through decades of experience, we are always driven by our customers’ growing needs for skills and services. We are renowned for producing plates of the highest quality, building and cementing our reputation over more than 40 years in business.

“Any third-party endorsement like this underlines the strength of that reputation,” he said. “As a certified partner, we now benefit from benchmarking and identification of best practice around quality control processes and production efficiency. Not only that, but the Esko Certification Program is also an excellent marketing tool for our business, enabling us to add value and promote an extra level of quality assurance to our customers.”

Pascal Thomas said that the XPS Crystal Certification Program is now open to all users of the innovative Esko XPS Crystal exposure unit. “As well as the external communication benefits Olivier referred to, certified members will be able to verify their plate making process against the industry benchmark,” said Pascal. “This also serves to help track plate quality over time and catch potential issues before they occur on press.”

The award winning Esko XPS Crystal technology optimally combines UV main and back exposure, using LEDs that always emit consistent UV light as opposed to traditional exposure frames, which use lightbulbs with fluctuating output. Winner of the prestigious FTA award, 2017 InterTechTM Technology Award, 2018 EFIA Technology award and the Red Dot Award for Product Design, the XPS Crystal delivers a simultaneous and optimally controlled UV main and back exposure to produce highly consistent digital flexo plates.

www.esko.com/es/products/digital-flexo-platemaking/xps-crystal/certification

www.medialliance.org