Redacción Alabrent

BM2 is the first machine in the world to have the capability to produce dispersion barrier coatings directly on the machine, producing barrier boards that can be recycled with normal paper waste due to having zero plastic content.“The interest in our new sustainable products has been massive. The new machine offers a wide range of interesting possibilities for converters, brand owners and designers alike. Another of the machine’s unique features is the ability to produce board with a silk matte surface, providing brand owners the possibility to make their product really stand out,” says Markku Hämäläinen, CEO of Kotkamills.

The Consumer Boards business will serve two main market areas. The first is the market for the production of packaging for food, confectionery, pharmaceuticals and cosmetics. The second is the market for food service boards for disposable cups and plates. All products are based on Nordic fresh forest fibres and come with the unique possibility of the addition of on-machine dispersion coated barriers to replace the non-renewable plastics traditionally used.

The new machine will provide an increase to the environmental performance of the site by significantly decreasing the consumption of electricity and water compared to the former paper production process. The consumption of water per tonne of CTMP will be almost halved compared to earlier.

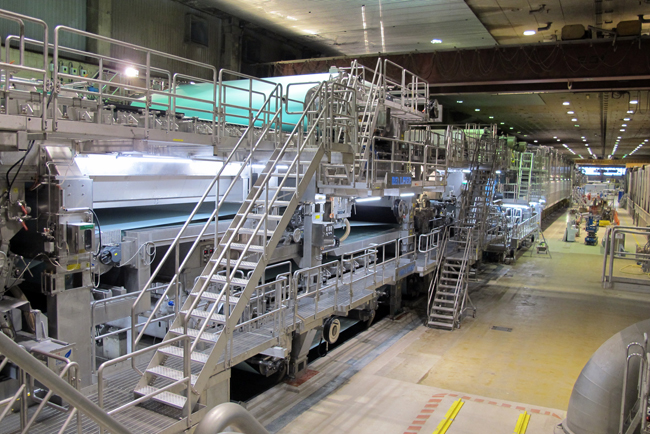

Kotkamills’ Consumer Board machine BM2 in short

- Production capacity 400,000 t/a

- Primary products: high-quality Nordic folding boxboard and recyclable barrier board for the packaging industry and food service sector

- Total investment 170 MEUR

- More than 5 MEUR has been invested in the effluent treatment plant, improving the cleanliness of the waste water

- Main machinery suppliers: Bellmer Vaahto Paper Machinery Oy (from the wet end to drying section of the machine) and Valmet (online coating section, reeler, winder and CTMP plant)