Redacción Alabrent

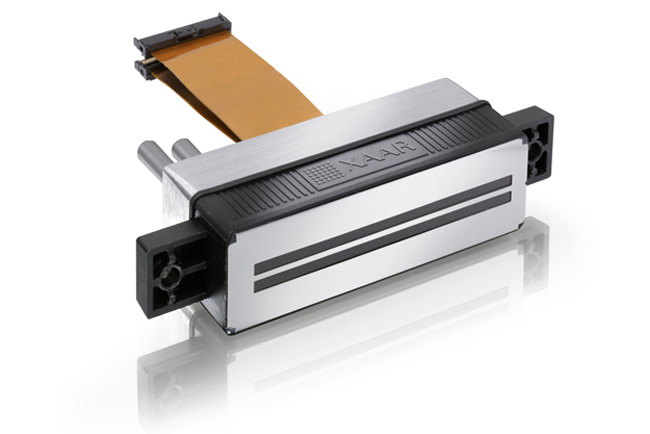

The new Xaar 1003 printhead family introduces an important new feature the XaarGuard™ which provides the ultimate in nozzle plate protection and, coupled with other design innovations, achieves the longest maintenance-free production runs in the industry*.In addition, the new Xaar 1003 provides a step forward in consistent print quality across the wide print widths used in many single-pass applications, due to Xaar’s new X-ACT™ Micro Electric Mechanical Systems (MEMS) manufacturing process. This innovation is a great example of how internal process improvements directly translate into customer benefits; Xaar was recently awarded Manufacturing Site of the Year by the prestigious National Microelectronics Institute in recognition of the company’s dedication to Continuous Improvement.

Like its predecessors, the new Xaar 1003 family of printheads combines Xaar’s unique TF Technology® with Xaar’s Hybrid Side Shooter® architecture so that ink is recirculated directly past the back of the nozzle during drop ejection at the highest flow rates in the industry. This ensures that the printhead operates reliably even in the harshest industrial environments and also in horizontal and vertical (skyscraper) jetting modes. Ink is in constant circulation, preventing sedimentation and subsequent blocking of the nozzles when jetting.

In response to market demand, the Xaar 1003 will be available in three variants. The Xaar 1003 GS12 (rich colours or higher speeds) for ceramics applications is first to be launched, closely followed by the Xaar 1003 GS6 (for fine detail) and the Xaar 1003 GS40 (for special effects). The other variants for UV applications will also be available later in the first half of this year.

“We are delighted to announce the new Xaar 1003 printhead family which is testament to our commitment to ensure our customers remain at the leading edge of single-pass industrial inkjet printing”, says Xaar’s Director of Marketing, Gillian Ewers. “Alongside improved performance and the maintenance free production runs, the Xaar 1003 is easy to install and is also backwards compatible with the Xaar 1002 and Xaar 1001 printheads.”

Xaar’s new flagship printhead family is the next generation of printheads which are trusted by manufacturers working in a wide range of applications such as ceramic tile decoration, labelling, direct-to-shape and other packaging printing, the production of wood laminates, glass printing and for many other manufacturing processes. The Xaar 1003 will be on show at drupa 2016 (Hall 6 Stand C05) and Ceramics China (Hall 8.1 Stand K032).