Redacción Alabrent

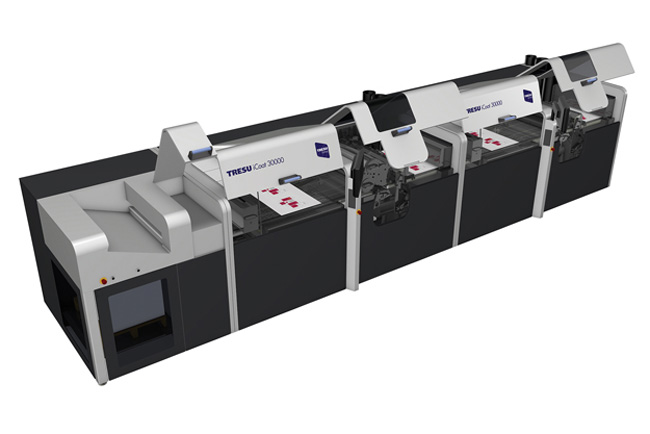

Designed for inline integration with the HP Indigo 30000 Digital Press, TRESU iCoat 30000 TWIN includes two flexo units capable of applying spot, partial or full surface coating immediately after the printing stage. The result is a seamless single-pass sheet-fed print and coating operation, resulting in efficiencies in logistics, material waste, setup time and handling.Søren Maarssø, chief operating officer, TRESU Group, comments: “The iCoat 30000 TWIN’s double flexo stations provide an effective way of enhancing functionality and aesthetic impact, with multiple combinations of UV-curable and water-based coating, in a single process.”

Combination varnish printing with the TRESU iCoat 30000 TWIN opens numerous creative opportunities. Examples of possible effects include a double full-surface coat for extra protection; juxtaposing matte with high-gloss; or combining full, spot or line effects, thus creating contrast or adding vividness to an underlying colour.

“The coater is an ideal complement to a digital workflow for high-end applications in cosmetics, pharmaceuticals, luxury food and drinks, and retail promotional packaging, especially where short runs, variable data, unique versions or personalisation are required,” adds Mr. Maarssø.

Capable of running 5000 sheets / hour on board substrates between 180g/m² (121.6 lb) and 500g/m² (337.8 lb), TRESU iCoat 30000 TWIN also features corona treatment, quick-change sleeve technology and the ability to switch from UV to aqueous varnish within a few minutes.

The TRESU iCoat 30000 TWIN makes its global début at the forthcoming DscoopX, Washington DC, USA, 5 - 7 March 2015.